60 mm hot end will spit out builds in nearly half the time at. However, there may be some stringing or wisping with the thinner layer heights.

You’ll get better prints with a slower build speed around 40 mm per second and by keeping the layer height on the lower end of the hot end’s spectrum.

Cetus3d slicer install#

Simply move through the software’s settings and withdraw any filament feeding the extruder, use the wrench and turn counter-clockwise to remove the hot end, install the new one and recalibrate the print height.Įach hot end has its strengths and weaknesses but lets users adjust the layer height to achieve specific results. Switching between hot ends is easy enough and can be done within minutes. 20 mm hot end, the details and accuracy will increase dramatically. These can be tackled by switching to the fine setting instead of the normal and slowing down the build speed to minimize artifacts and increase the finished build quality. While the print bed allows for good adhesion, there are some issues with layer adhesion. Once the bed is leveled, printing can begin. Leveling can be done with a 9-point matrix and assisted with the included bundled Up Studio software. The build plate has to be leveled manually and does not come heated. The build area has a special coating applied to the build plate for better adhesion and easy print removal.

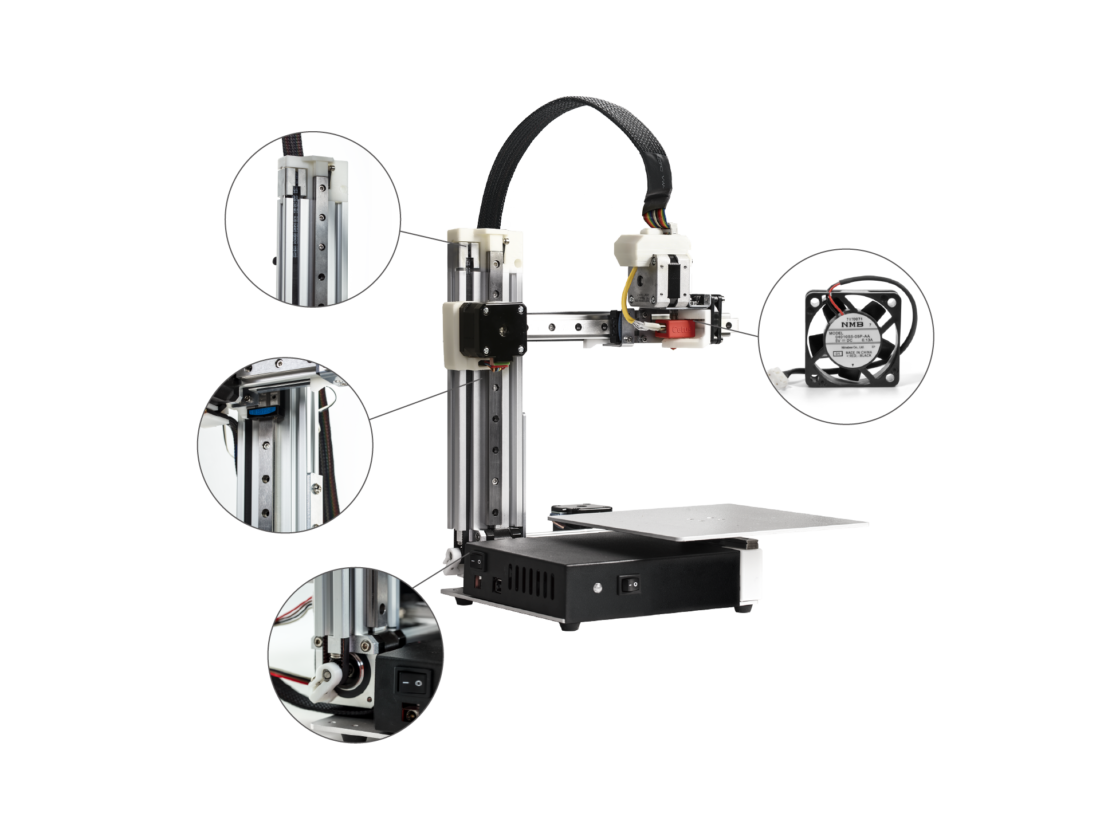

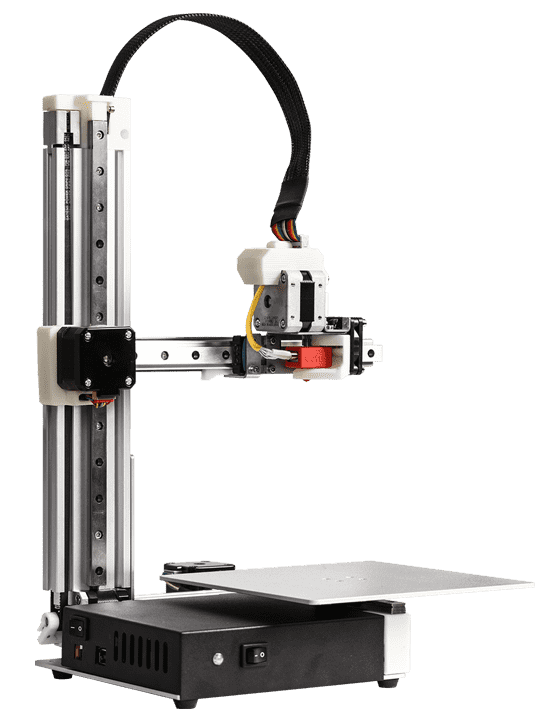

This explains the difference in the build space too where the extended version tops out at 11 inches as opposed to the standard’s 7 inches. The Tiertime Cetus extended version is the same size as the standard MK3 in length and width, but the height is significantly different at 16.8 inches in comparison to the standard’s 10.75 inches. There are some 3D printed parts and the printer is boasted to be mod-friendly. When it comes to looks, again, simplicity is the goal with its sturdy aluminum extrusions. Sending jobs to the printer wirelessly or through the USB cable give it a wider range of functionality.

Cetus3d slicer upgrade#

One upgrade included in both versions of the printer is the ability for untethered printing. Adding the Cetus MK3 Extension board will support the proprietary enhancements. The company warns that modifications and add-ons like the heated bed and automatic leveling probe won’t be compatible with the printer, so adjustments will have to be made. The printer supports slicing softwares Simplif圓d, Slic3r, Cura, Octoprint and others since Tiertime lets users modify the Tiertime Cetus into a complete open-source 3D printer.

Cetus3d slicer windows#

Speaking of settings, the Tiertime Cetus 3D printer allows custom material profiles to be created for third-party filaments for the Windows version of its software. However, even though it prints with this ample assortment of building materials you’ll have to purchase the heated bed upgrade to print with exotic filaments and materials with more extensive temperature settings.

This is a great perk since the printer is capable of extruding a wide variety of filaments. One of the first things to notice is that it comes with a. This Tiertime Cetus MK3 review showcases the features provided by the MK3 in both the standard and extended versions of the printer giving the good, the bad, and the in-between.

60 mm direct drive single extrudersĬHECK PRICE ON AMAZON Design & Features of the Tiertime Cetus PLA, ABS, Tough ABS, PETG, Nylon, Wood, TPU Let’s get into the tech specs: Tiertime Cetus Technical Specsġ80 mm x 180 mm x 180 mm (7 in x 7 in x 7 in)ġ80 mm x 280 mm x 180 mm (7 in x 11 in x 7 in)

Cetus3d slicer series#

It offers a series of upgrades and add-ons that both enhance and customize the machine to your liking. Whether you’re looking for the Tiertime Cetus or its extended version, it’s useful to know that Tiertime takes a simplistic approach to its line of 3D printers.

0 kommentar(er)

0 kommentar(er)